Types of Armour

Armoured Plate

The First world tanks and early tank production used Armoured plate steel which is carbonised by heating the steel in the presence of carbon (usually charcoal) for long durations (often several weeks), this allowed the carbon to be absorbed into the surface of the steel plate to depths of up to 20 thousandths of an inch, the subsequent heat treatment of the plate produced a material with a malleable and shock resistant core and an extremely hard outer face. Unfortunately this type of steel was very prone to splinters breaking off the surface when hit, causing injury to the crew inside.

Homogeneous Armour Plate

Homogenous armour plate was developed between the First and Second World wars. Armoured steel must be hard, yet also be able to withstand shock in order to resist high velocity metal projectiles. Steel with these characteristics is produced by rolling appropriately sized cast steel billets into sheet form. The grain structure which exists in any cast metal creates lines of weakness throughout the casting making it very brittle. Rolling the cast steel billets stretches the grain structure to form long lines, this eliminates the areas of weakness and enables the stresses within the steel to flow throughout and the effects of impact to be dissipated.

Rolled Homogenous Armour is so called because, due to the rolling process, its structure and composition is uniform throughout its section.

Sloped Amour

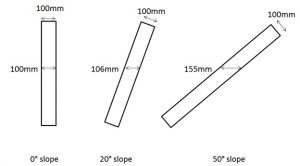

Sloped armour is, as its name suggests, positioned at an angle rather than in a vertical or a horizontal plain; it is a way of achieving a thicker armour without increasing the weight of the vehicle. If there is 100mm of frontal armour on a Main Battle Tank, when measured through a horizontal line, when this is sloped at 20 degrees the thickness of the armour will be increased to 106mm; if one lays the armour at 50 degrees the thickness would in turn be increased to 155mm, thus increasing the frontal protection of the tank. This was first adopted by the Russians in 1942 when they produced the first T34/75.

Sloped armour is, as its name suggests, positioned at an angle rather than in a vertical or a horizontal plain; it is a way of achieving a thicker armour without increasing the weight of the vehicle. If there is 100mm of frontal armour on a Main Battle Tank, when measured through a horizontal line, when this is sloped at 20 degrees the thickness of the armour will be increased to 106mm; if one lays the armour at 50 degrees the thickness would in turn be increased to 155mm, thus increasing the frontal protection of the tank. This was first adopted by the Russians in 1942 when they produced the first T34/75.

Spaced Amour

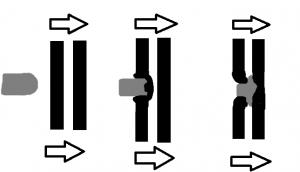

How spaced armour works

Spaced Amour is, again, exactly as its name suggests. A second layer of armour is added to the outside of the vehicle with a gap in between (rather like a cavity wall). The principle is that the hollow space disrupts the shockwave caused by the impact, deflecting the projectile and forcing it to lose momentum. This works effectively for all types of weapons, armour-piercing or Shaped Charge The second layer of armour need not necessarily be steel, but in general practice it is. Spaced Armour first came into use towards the end of the Second World War. In archive film clips German vehicles can be seen with additional armour plates added on.

Chobham Armour

The manufacture of Chobham Armour is still covered by the Official Secrets Act and little is known about its specifics. It is believed to be made from many layers of different energy absorbing materials compressed together under extreme pressure and heat to make a very dense material. This material is then added in blocks to the exterior of a vehicle.

Bar/Slat Armour

On today’s modern armoured vehicles we use Bar Armour as a secondary armour. Its purpose is to detonate warheads (anti tank rocket propelled grenades) before they reach the main body armour. Bar Armour was developed to keep vehicle weight down whilst still maintaining the capability to detonate warheads.