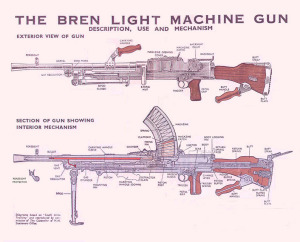

BREN LIGHT MACHINE GUN

THE GUN .303” BREN, LIGHT MACHINE GUN. Without any shadow of doubt, the Bren has to be the finest light machine gun ever made. It was developed from the Czechoslovakian series of ZB guns, which enjoyed widespread sales around the world from 1924 onwards and were widely used by the Germans during WW2.

The first gun trialled by us was the ZB26 BRNO in 1927 and the gun, tripod and ammunition cost £209/9/0. This Gun was in 7.92mm. Calibre,(not .303”). Further modifications were carried out to ensure total reliability, after reducing the calibre from 7.92mm (.311”) to .303”, the change from the rimless 7.92mm to the rimmed .303” cartridge resulted in the familiar curved magazine used on the Bren. This Brno gun was known as the ZB30 Model 1.

The final Czechoslovakian gun modified for us was the ZB34, Model 4, type 2. Trial versions of this gun were manufactured by the Enfield Small Arms Factory with initial tooling costs of £30,000. By April 2nd 1936. the tooling costs for this gun had risen to £60,000. As war seemed very likely by this time, 84 guns were ordered from Brno and a quantity of these were shipped to Canada with a view to production there. Finally, the ZB with all the latest Enfield modifications was produced on March 12th 1937. The first Enfield manufactured gun was assembled on September 3rd 1937. It was of course, known as the BREN. (BR. Brno factory in Czechoslovakia, and EN. Enfield factory)

It was quite clear after the dreadful losses following the evacuation from France that these “de-lux” guns had to be simplified, indeed three consecutive versions of the Mark I gun followed.

Simplification involved, removal of the forward dovetail, strengthening ribs on the body, bevels and lightening cuts omitted and scores more to follow, resulting eventually, in the Mark 2, a utility gun far better suited to manufacture during wartime. The Germans adopted the Bren during W.W.2, they called it the 7.7mm (.303”) MASCHINENGEWEHR 138 (e). They not only used it as a front line gun but also as an occupation gun. They had a very high regard for it.

Although the magazine was designed to hold 30 rounds of .303” and care had to be taken during loading to ensure that the cartridge case rim was in front of the previous rim, it was found to be far more reliable if only 28 rounds were loaded into the magazine. The gun had a cyclic rate of fire of 500 rounds per minute and 25 magazines were issued per gun. A spare barrel was carried and this could he changed in 2 to 3 seconds but it was not uncommon to see the barrel glow with heat. The method used to try to cool the replaced barrel was often by unconventional methods that need not be described here, but the rapid change barrel using the carrying handle was a godsend to prolonged fire.

Various anti-aircraft mounts were developed, many using a pair of guns and 100 round drum magazines which were also used by specialist troops such as the Long Range Desert Group.

The Bren was not only used during the war in various marks, it continued in service post war in .303” and when the Rifle 7.62mm. L.1.A.1 (Self-loading rifle) was introduced in 1957. The Bren was converted to the NATO round, and in both calibres, as well as in 7.92mm, is still to be found in widespread use around the world (2006).

THE GUN .303” BREN. LIGHT MACHINE, MK 2

The Mark I gun was unsuitable for “mass production”. Whatever simplification was introduced, it was still a gun requiring massive machining operations to produce. However, the Mark 2 went someway to making things a little easier. The changes from the 3rd pattern Mark 1 as follows.

- The drum sight replaced by a folding sight with venire click adjustment for elevation

- Elimination of many mainly external machining details to the gun body.

- The folding cocking handle replaced by a fixed handle.

- A much simpler butt without buffered butt plate. Shoulder strap, lower butt handle and swivel locked butt pin

- New barrel assembly with separate flash eliminator, foresight assembly & only the gas block in stainless steel

- Spring loaded butt plate replaced with a simple pressing with top loop for sling fitment.

- Bipod with non-adjustable legs of much simplified design.

- The gas shield at the front of the body a simple stamping instead of the integrally machined Mk. 1.

- Double return/recoil springs in the butt rather than the single spring of the Mark 1. NOTE. The Australians, always looking for unofficial improvements, found that if the striker spring from a Mills 36 Grenade was slipped over the rod spring return, the gun would have a much quicker rate of fire.

It must he noted that nearly ALL Bren’s will have parts that perhaps don’t strictly belong to particular marks. This is seen especially with this gun (Bren Mk.2) because as improved parts such as folding cocking handles and adjustable bipod legs became available, the emergency early war time parts were discarded in favour of better components. Nearly all parts of the Bren are interchangeable

GUN, 303” BREN, INSTRUCTIONAL, SECTIONALISED

Those instructing on the Bren would call the gun simple. This description was rightly used because the working parts appeared to be as minimal as possible. i.e.

- Body group.

- Butt group.

- Piston & Breechblock.

- Barrel.

- Bipod.

Of course, these groups could be detailed stripped either by the user or armourer but in general, this was as far as field stripping required. However, to see how the trigger mechanism worked in fully automatic, single shot or safe mode, how the breechblock was pushed up forward of the locking shoulder in the body, how the piston was pushed to the rear by gas directed through the gas regulator or indeed anything else internally, either wall charts were used, or cut away demonstration guns needed. Cut aways were always used for instructing armourers during training and were first class methods for the instruction of small groups. Components used for these guns were generally unserviceable parts or ex-Drill Purpose bits thus avoiding wasting components that still had some life left in them. It was normal practice to highlight cut away areas with red paint so as to show where cuts had been made. Training using cut away instructional firearms is far better as it is easy to see what component acts with another to carry out functioning of the gun during its firing cycle.

As an aside, it is often very sad to see that many service firearms chosen for sectionalising are in fact early or prototype guns that would be highly collectable today. We are as a nation, very good at the total destruction of our history. No thought seems to go into the preservation of early or rare exhibits. It is highly probable that the only reason why these “non guns” have been preserved is that they seem interesting and are not normally “held on charge” when the service guns become obsolete, and thus, might be able to “get lost in the system”, depending on the whim of the Quartermaster!

These pre-war BREN guns were very complex in their manufacture and were a devil to produce. Note the dial drum rear sight graduated from 200 to 2,000 yards, while forward of that is an additional identical dovetail into which fitted a telelensatic sight, only made in very small numbers for trials and never adopted. Note the very rare butt-strap, another expensive pre-war fitment, made under contract by Birmingham Small Arms, (BSA) as was the underslung butt-handle, another pre-war luxury soon abandoned with the outbreak of war in 1939. This 1938 gun has all the expensive machining operations done either for weight saving or to incorporate pre-war luxuries of manufacture. This gun weighs 22 lb., 2 oz. The war time version without all the lightening luxuries weighs 23 lb., 3 oz. It might not seem much of a saving, but to the overburdened British soldier, every ounce seemed like a ton after a few miles These pre-war guns were also issued with the tripod, containing an anti-aircraft fitting so that it could he used at extreme ranges. This cumbersome addition seldom saw the light of day after Dunkirk.